USEFUL INFO ABOUT THE NATURAL GAS UNITS VENTING SYSTEM

(1) ___ Gas tankless water heaters don’t have to use indoor air for combustion.

(2) ___ You don’t always need two ventilation pipes, even for direct-vent units.

(3) ___ You don’t have to go through the roof.

(4) ___ With an outdoor unit, you don’t need to vent at all.

(5) ___ With a condensing tankless water heater, you don’t need metal venting.

(6) ___ You don’t have to have a box stuck to your wall.

(7) ___ You don’t always need separate vents for multiple water heaters.

(8) ___ Your venting system doesn’t have to be ugly.

(9) ___ It is Time to buy a Bundle Kit Tankless Water Heater!

The proper venting Materials and procedure for the venting of the Natural Rise Power Gas Series are as followed :

The preferred material for these heaters is B-Vent which means : doubled walled, galvanized metal outside, polished aluminum inside.

The GA5 and GA10 both require 4” venting and the GA16 requires 5”, but the supplied adapter may be used to go up to 6” (Never reduce in size).

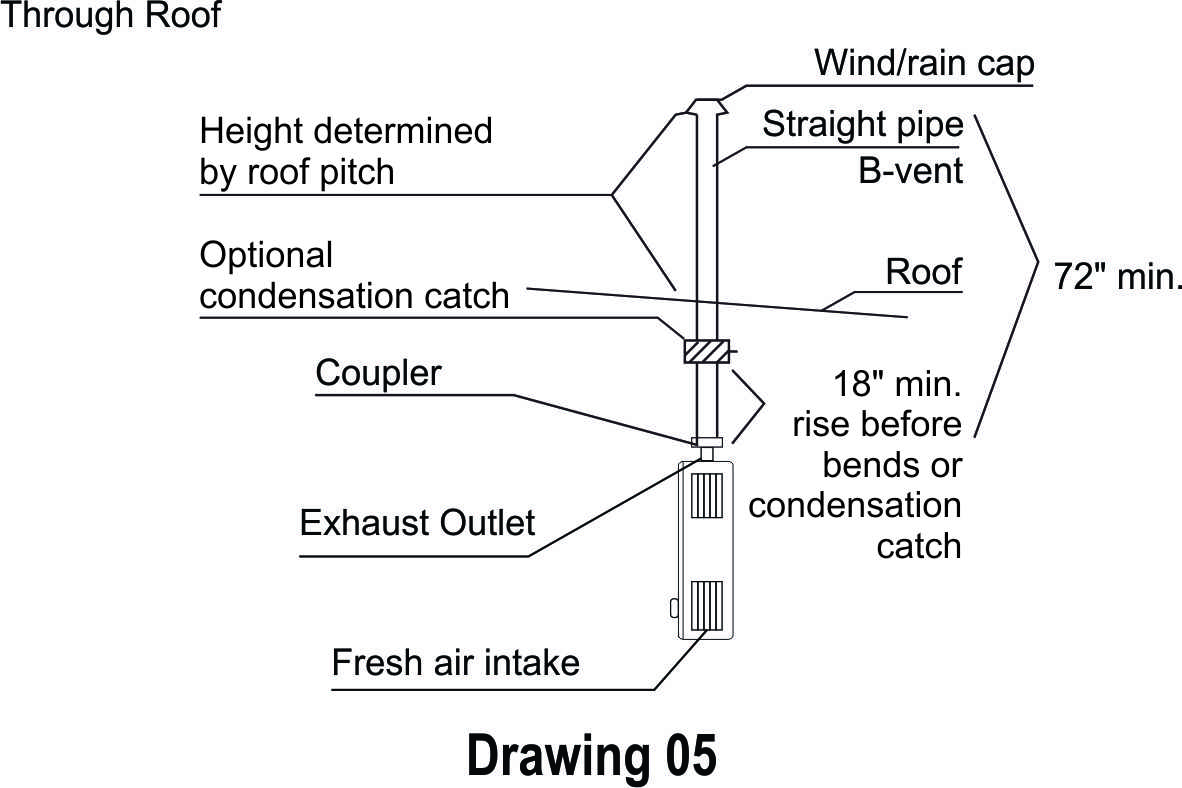

You must establish an 18” collar rise before installing any bends or condensation catches.

Never install a 90 degree bend directly on top of the heater.

The minimum height allowed is 6 feet, this is to allow enough pipe to heat up to properly vent the gases and moisture from combustion.

A straight vertical run is preferable.

IF horizontal runs are necessary then they must always be sloped up at least .25” for every foot and must be kept shorter than 75% of the total vertical length.

Never terminate the venting horizontally, you need the last bit of vertical run to “pull” the remaining gasses that may have cooled in the horizontal run.

Many municipalities require a “chase” to be added up to the roof line for any venting running up an exterior side wall of a structure.

Please check local guidelines.

IF venting through the roof then the termination height will depend on your roof pitch.

IF condensation is a concern for a specific installation then other more specialized materials should be used most common is Z-Vent (double walled stainless steel on both in and outside layers).

IF there are any deviations from these guidelines then please seek the help of a qualified HVAC technician.

Improper venting is risky, could be hazardous, dangerous.

Question: What size is the Flue pipe on the power natural gas and propane units and do they come with a through the wall kit?

ANSWER: The vent pipe for the gas tankless units is 4 inches. ALL units come with a Stainless Steel Chimney adapter piece.

According to ANSI code, gas tankless water heaters normally require stainless steel, category II/III vent pipe. This is due to the fact that gas tankless water heaters actually burn at a higher BTU rating. As such, the gas is extremely hot when it leaves the water heater, but cools quickly. This cooling process results in condensation which could eat through regular galvanized pipe.

We carry the Z-Flex vent pipe. For tankless water heaters, it is single walled for model units like the 22L NG DP – 45 HI and the 12L NG DP

It requires less pipe and as such, less expensive.

When doing a horizontal run, your maximum lengths are as follows:

►1 Elbow: 47′ 6″

►2 Elbows: 42′ 6″

►3 Elbows: 37′ 6″

Each Elbow is equivalent to 5′ of Straight Pipe.

You will need to determine how many additional feet you will need as well determine if you will need a condensation drain.

There is a maximum vent run of 20 feet, subtracting 4 feet for every 90 degree elbow in the run.

Just so you know ANY Vertical Venting Installation with more than a 5′ run length requires a vertical condensation drain pipe as well.

When installing a vertical vent stack, you will need the following pieces:

►Universal Appliance Adapter

►Drainpipe For Condensation

►Flashing

►Storm Collar

►Rain Cap

►Straight Pipe

Please NOTE : A Termination Hood Or Straight Pipe Section Must Be Equipped With A Damper/Backflow Preventer Is Mandatory To Ensure That Freezing Air Does Not Come Back Down Through The Vent Stack.

This May Cause Freeze Damage Internally In The Water Heater And Is Not Covered Under Warranty.

Please NOTE that The Tankless Water Heaters Web Store is an Online Store specializing in Tankless Water Heaters, Parts & Accessories Sales and does NOT provide any kind of installation service.

We do however have a list of Plumbers, General Contractors, Electricians that will be interested in providing installation service totally independent from our sales.

Please send an email to see if we do have availability of such service providers in your town.